Ramsey's Pro-Line Belt Misalignment Switch ROS-2E-3-4-NPT

NEMA 4 Enclosure

cCSAus rated for Class II, Div 1 & 2, Group E, F & G applications

Rated for use in applications between -40° to +185° F (-40° to +85° C)

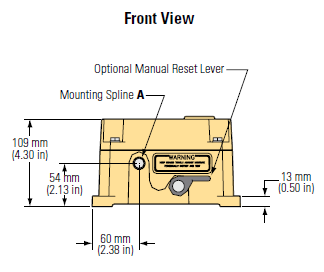

Actuator arm adjustments: 22.5 degree increments from vertical

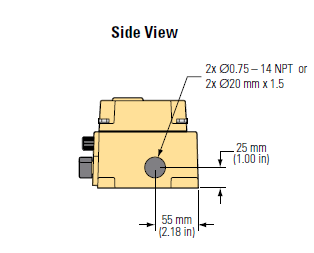

Conduit Openings: Two threaded 3/4-14 NPT

Contacts: (2) SPDT switches

Contact rating: 10 Amps, 250 VAC

PRODUCT LITERATURE

Resellers please contact us for bulk discounts.